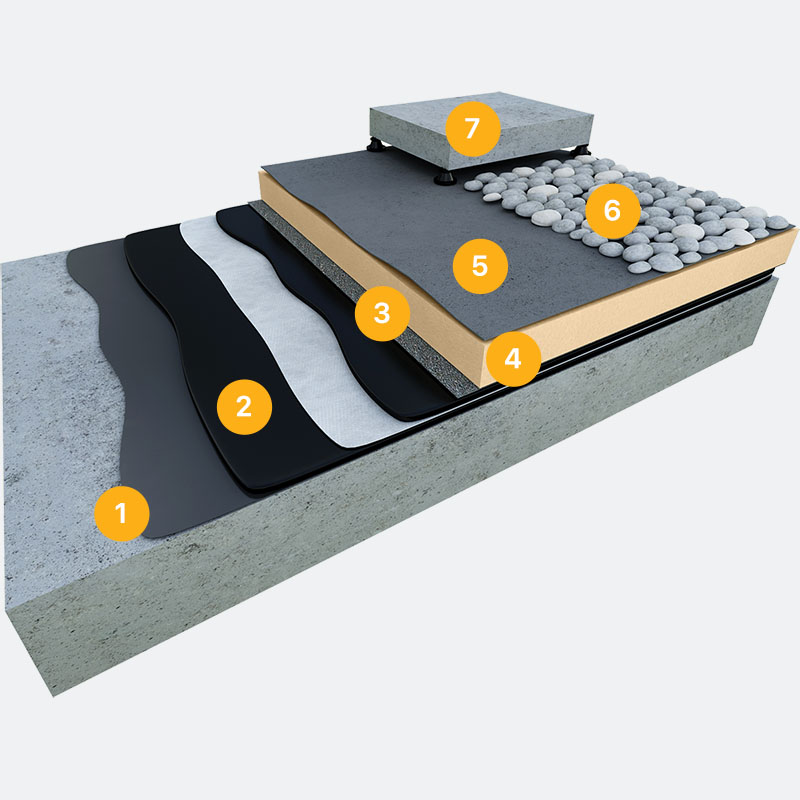

Permatec Inverted Ballasted Roof System

Most popular hot melt system build up, usually installed onto a concrete deck (alternative decks can be used).

Most popular hot melt system build up, usually installed onto a concrete deck (alternative decks can be used).

Substrate preparation

Before applying the Permatec fully bonded system, ensure the surface of the substrate (concrete, plywood, calcium silicate board, metal/insulation composite, etc.) is properly prepared. Joints, cracks, or interfaces between different substrate materials should be detailed according to Permatec Standard Drawings and Masterspec 4414AP specifications.

Membrane application

Using a suitable spreader or squeegee, apply the first coat of hot Permatec compound to the prepared substrate with a nominal thickness of 3mm. While the Permatec compound is still hot, brush the Permaflash-R polyester reinforcement into it. Ensure all Permaflash-R laps are at least 75mm wide and fully sealed with the Permatec compound. Apply the second coat in the same manner, ensuring complete coverage of Permaflash-R with a nominal coating thickness of 3mm. Finally, protect the second coat of Permatec.

Protection

For standard protection, utilize Permaguard-F, a sand surfaced bitumen membrane, applied directly to the second hot and tacky coat of Permatec. This layer covers the main horizontal area and prepares it for subsequent components like insulation, separation layer, and loading coat (stone ballast, concrete paving, etc.). Additionally, Permaguard-F is suitable for use on unexposed detail items. Ensure quick rolling of the Permaguard-F protection layer into the hot Permatec, with at least 75mm laps sealed using hot Permatec compound.

Permaguard-M, a slate surfaced bitumen membrane, is specifically designed for exposed upstand details. Apply it to the second coat of Permatec through controlled torch application, ensuring at least 75mm laps that are fully sealed.

Detailing

Incorporate precise detailing of rainwater outlets and penetrations in the roof waterproofing system, following Permatec Standard Drawings and Masterspec 4414AP specification.

System components

A standard Permatec inverted roof system consists of various components, including XPS insulation with thickness complying with “R” values requirements, a water control layer, and a loading coat (stone ballast or concrete paving).

[get_downloads_system]